-

Need help?

+91 9311163794

-

Mail Us @

sales@subhotheaters.com

Aluminum & Brass Casted Heaters

×

❮

![]()

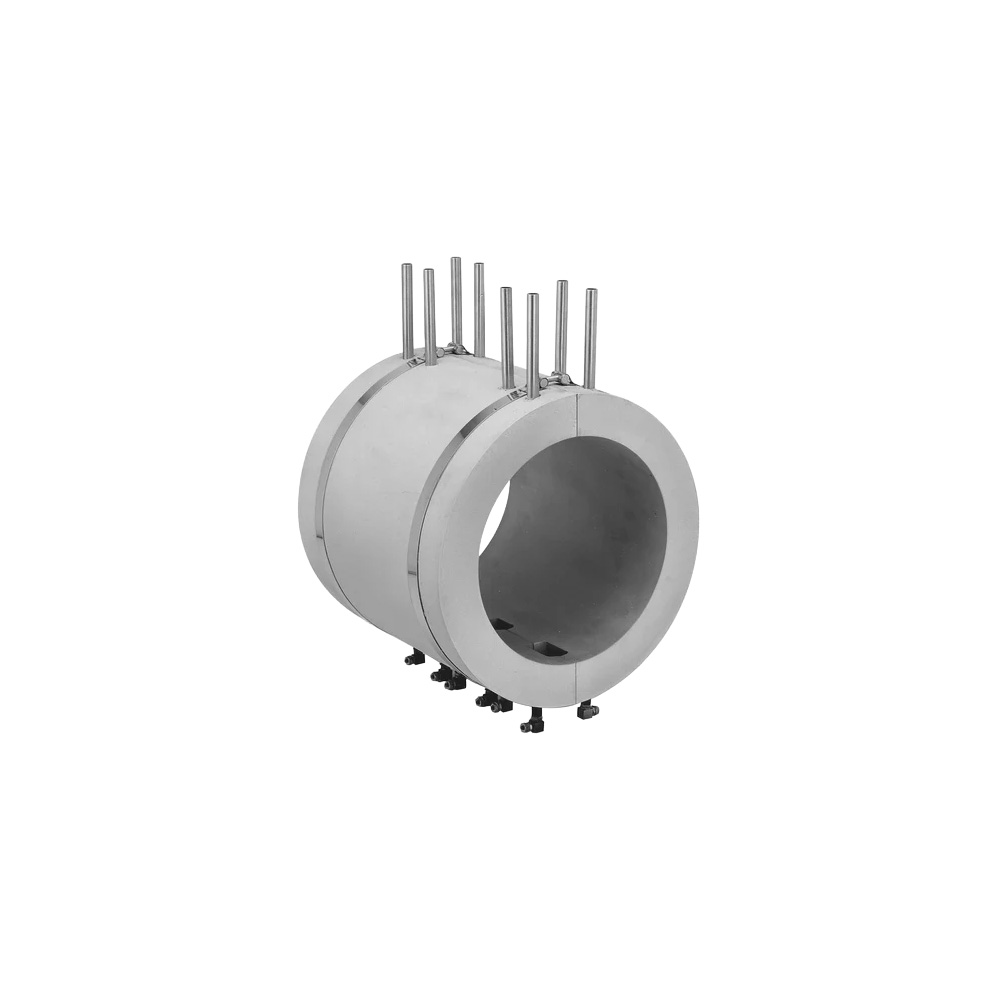

Aluminum & Brass Casted Heaters

Casted heaters are high-performance industrial heating solutions manufactured by embedding tubular resistance coils into precision-cast bodies of aluminum, brass, or iron alloys. This unique construction ensures exceptional heat transfer efficiency, thermal stability, and durability under demanding operating conditions.

With customizable shapes and sizes, casted heaters are specifically engineered to match the contours of molds, platens, or specialized equipment surfaces, ensuring uniform heat distribution across the entire contact area. Their excellent thermal conductivity minimizes heat lag, making them ideal for applications where rapid heating cycles and accurate temperature control are critical.

Advantages

- High Thermal Conductivity – Rapid heat-up and uniform surface temperature distribution.

- Custom Geometries – Cast to exact shape of the part or machine surface for maximum coverage.

- Integrated Cooling – Supports liquid/air cooling for temperature-sensitive processes.

- Durability – Rugged casting resists corrosion, wear, and mechanical stress.

- Precision Heating – Thermocouple/RTD integration for accurate thermal regulation.

- Energy Efficient – Direct contact heating minimizes losses and improves efficiency.

- Long Service Life – Stable design reduces maintenance requirements.

Applications

- Plastic & Rubber Industry – Extrusion and compression molding platens, thermoforming molds.

- Packaging Industry – Sealing, cutting, and forming equipment.

- Semiconductor Manufacturing – Precision process tooling requiring stable thermal conditions.

- Food Processing – Heat sealing and forming in packaging machines.

- Medical & Laboratory – Controlled heating fixtures for sterilization or testing.

Features

- Cast body in aluminum, brass, or iron for different thermal properties.

- Embedded NiCr heating coils packed with MgO for uniform heating.

- Optional cooling channels for liquid or forced-air cooling.

- Integrated thermocouple pocket for temperature monitoring.

- Custom mounting flanges or brackets for easy installation.

- Suitable for single-phase or three-phase operation.

- Rugged, corrosion-resistant construction for industrial environments.