-

Need help?

+91 9311163794

-

Mail Us @

sales@subhotheaters.com

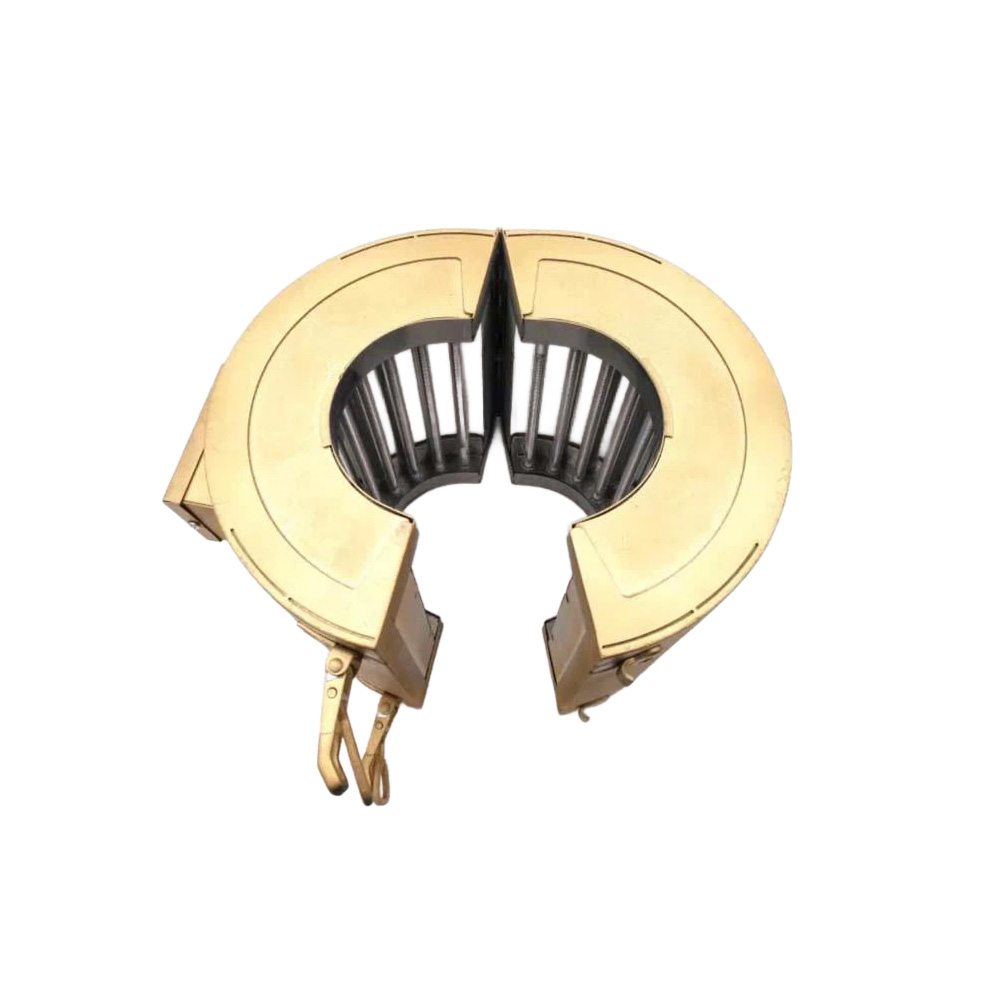

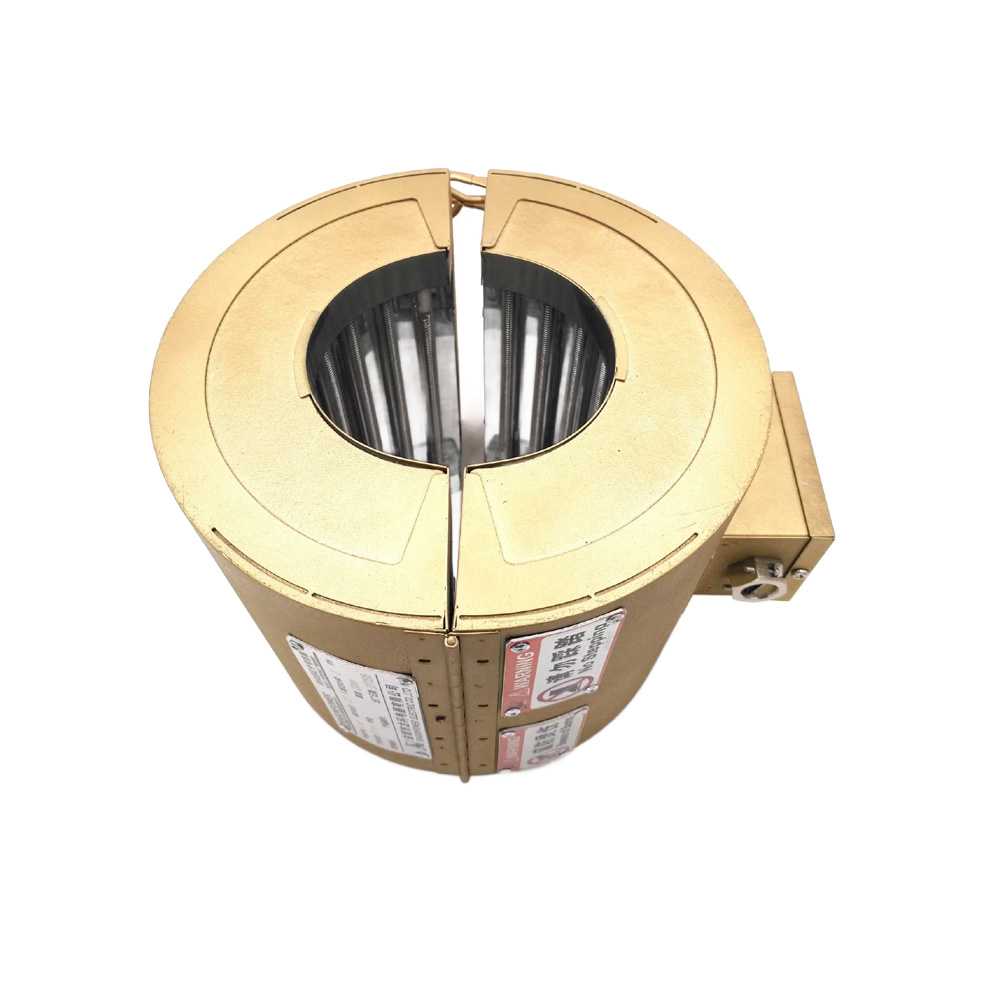

Nano Infrared Band Heater

×

❮

![]()

Nano Infrared Band Heater

The Nano IR Heater by Subhot Enterprises Pvt. Ltd. is a high-performance infrared heating solution engineered for precision, efficiency, and durability. Designed with high-purity quartz IR tubes, advanced resistance elements, stainless-steel reflective plates, and ceramic fiber insulation, it ensures uniform heat distribution with minimal energy.

Its compact modular design makes it easy to integrate into industrial heating systems, while the optional blower assembly provides forced-air cooling to enhance service life and temperature stability. With a service life of over 8 years and a power range of up to 12 kW, the Nano IR Heater is a reliable and energy-efficient choice for industries such as plastics, packaging, coating, curing, and R&D applications.

Advantages

- High Efficiency :Delivers concentrated infrared energy with minimal heat loss, reducing power consumption.

- Long Service Life : Durable quartz tube and robust insulation ensure >8 years of operational reliability.

- Precision Heating: Uniform IR emission in the 2–10 μm range for targeted, controlled heating.

- Versatility : Can be used in multiple industries including packaging, plastics, coatings, and R&D.

- Easy Maintenance : Modular quartz tubes and simple mounting design allow quick replacement.

- Durability : Corrosion-resistant stainless-steel construction with hightemperature ceramic insulation.

- Flexible Operation : Optional forced-air blower ensures stable temperature control and extends tube lifespan.

Applications

- Plastic extrusion and injection molding barrel preheating

- Web drying and curing in packaging and printing lines

- Infrared heating tunnels and stamping presses

- Surface and mold preheating

- Coating and adhesive activation processes

- High-efficiency IR heating for laboratory and R&D

Features

- Compact, low-profile design for space-constrained installations

- Uniform infrared emission for precise heating applications

- Modular quartz tubes for easy replacement and maintenance

- Stainless-steel reflective layer for enhanced heat efficiency

- Ceramic fiber insulation reduces backside heat loss

- Optional forced-air cooling system for extended service life

- Energy-efficient operation compared to conventional radiant panels