-

Need help?

+91 9311163794

-

Mail Us @

sales@subhotheaters.com

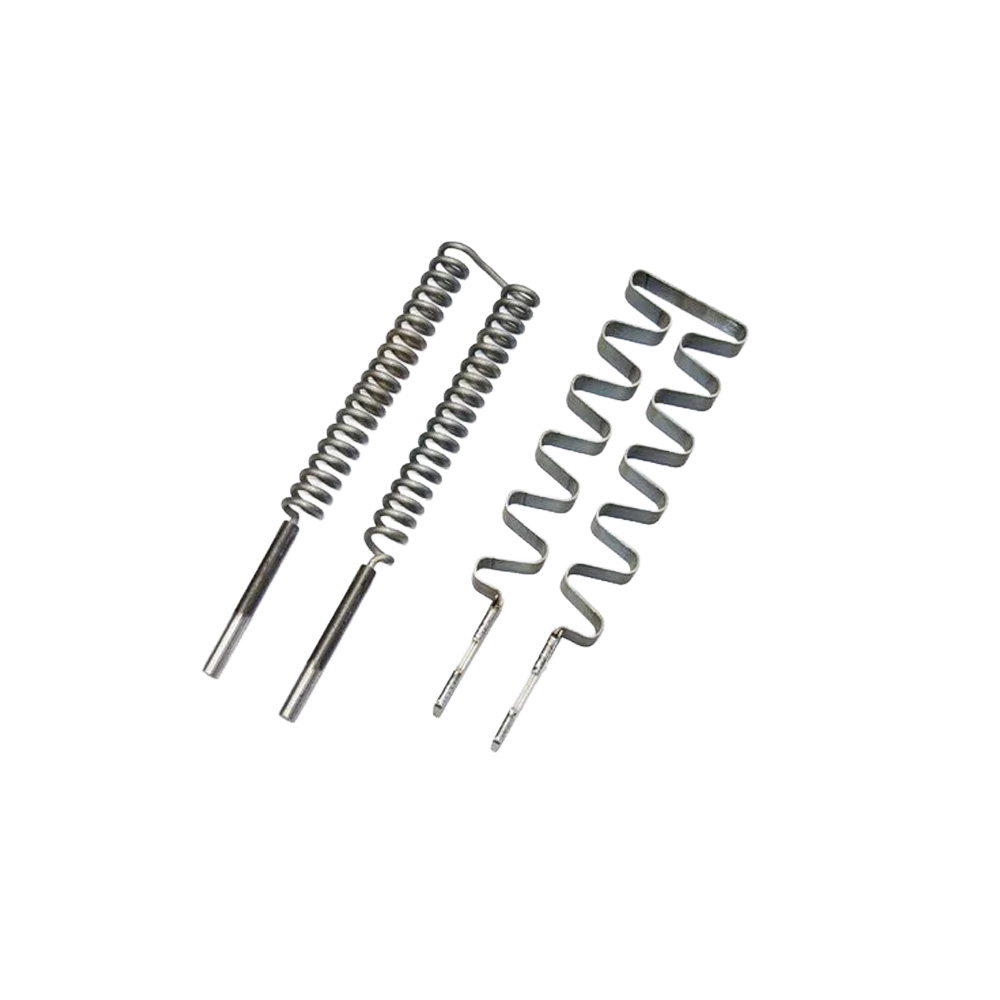

Furnace Strip Heater

×

❮

![]()

Furnace Strip Heater

Furnace Strip Heaters are flat, high-performance electric heaters designed to provide uniform surface heating at elevated temperatures. Built on a ceramic substrate with resistance wire bonded securely, these heaters deliver fast thermal response, consistent heat distribution, and energy-efficient operation.

Due to their compact and low-mass design, furnace strip heaters are ideal for hightemperature applications such as plastic molding, hot metal forming, laboratory instruments, sealing bars, and infrared heating panels. Their durable ceramic insulation, robust terminal connections, and optional protective coatings make them highly reliable even in harsh industrial conditions.

Advantages

- High-Temperature Capability – Operates up to 1100 °C without thermal degradation.

- Precision Heating – Accurate watt density control ensures uniform process heating.

- Energy Efficiency – Low thermal mass minimizes power usage during cycling.

- Durability – Resistant to thermal shock, abrasion, and harsh chemicals.

- Versatile Design – Suitable for flat platens, nozzles, sealing bars, and custom fixtures.

- Reliable Operation – Stable resistance elements ensure long-term performance.

Applications

- Plastic molding nozzles and platen heating.

- Hot metal forming dies and press equipment.

- Infrared heating panels and radiant systems.

- Laboratory and analytical instruments.

- Cutting, sealing, and shrink-wrapping machinery.

- Industrial furnaces and controlled heating zones.

Features

- Rapid thermal cycling with minimal overshoot.

- Uniform surface emissivity for consistent heating performance.

- Low-mass ceramic body reduces energy consumption.

- Easy installation with pre-drilled mounting holes.

- Long service life with stable element retention.

- Available in custom shapes, sizes, and heating patterns.