-

Need help?

+91 9311163794

-

Mail Us @

sales@subhotheaters.com

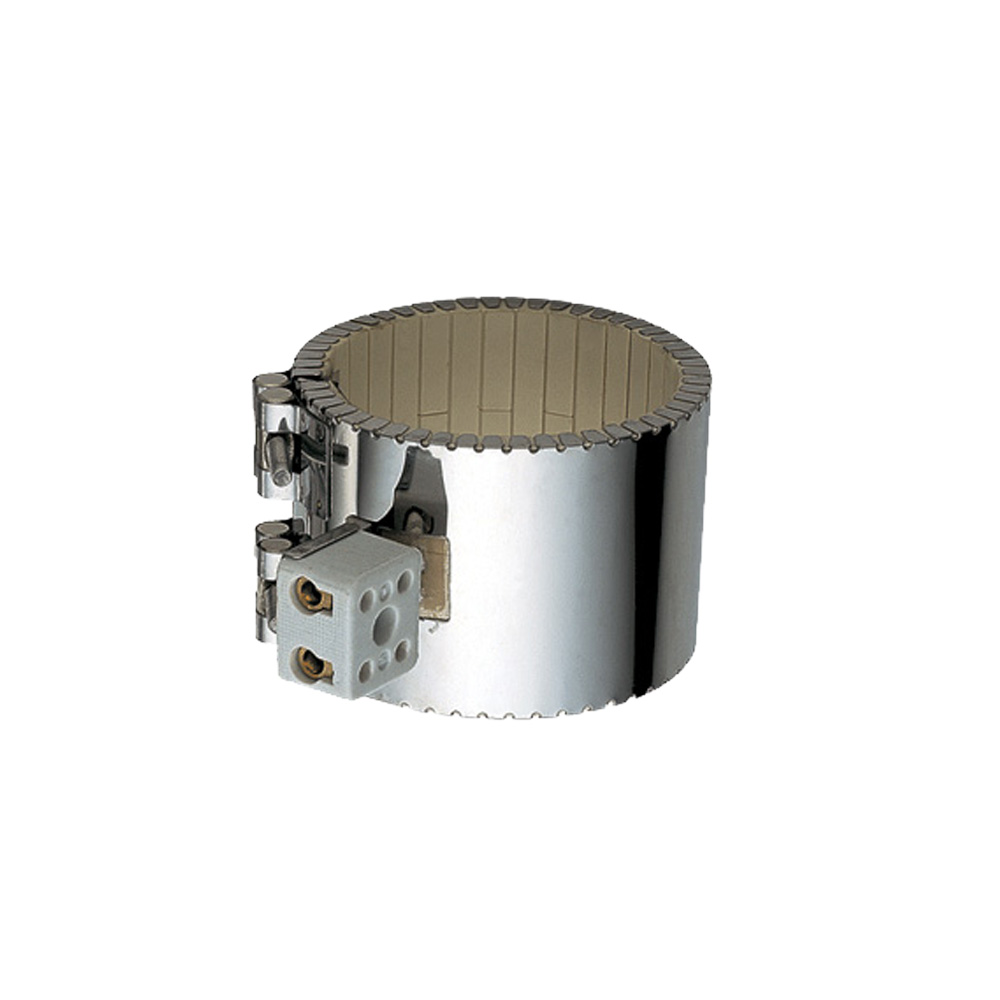

Ceramic Band Heater

×

❮

![]()

Ceramic Band Heater

The Ceramic Band Heater by Subhot Enterprises Pvt. Ltd. is designed for hightemperature and energy-efficient heating of cylindrical surfaces such as barrels, nozzles, and extrusion machines. Unlike mica heaters, ceramic band heaters utilize ceramic insulation (steatite), which not only conducts heat by conduction but also radiates it effectively, providing a higher degree of thermal efficiency.

Built with a precision-wound Nichrome resistance coil embedded in ceramic halves, enclosed in a stainless steel or aluminum-clad sheath, these heaters ensure uniform heat distribution, reduced energy consumption, and a longer service life. They are widely used in plastics, packaging, chemical, and semiconductor industries, where stable high-temperature heating is essential.

Advantages

- Energy Efficiency : High-density ceramic insulation lowers energy consumption compared to mica heaters.

- High-Temperature Capability : Can operate reliably up to 550 °C, making it suitable for demanding applications.

- Uniform Heating : Combination of conduction and radiant heating provides even temperature distribution.

- Long Service Life : Durable stainless-steel sheath and ceramic insulation ensure extended operational reliability.

- Flexible Design : Available in multiple diameters, widths, watt densities, and custom shapes, with segmental construction for large barrels.

- Process Control Options : Supports optional thermocouple integration, thermostat control, and forced-air cooling fins for precise heating management.

Applications

- Plastic Processing Industry – Barrel heating for injection molding & extrusion machines

- Moulds, Dies, and Nozzles – For precise temperature maintenance

- Extrusion Lines – Continuous barrel heating applications

- Waste Incineration & Pipelines – Maintaining controlled heating in flow lines

- Semiconductor & Electronics – Process equipment requiring stable high temperatures

Features

- Superior ceramic insulation reduces energy losses

- Heat transfer by both conduction and radiation ensures uniform distribution

- Capable of withstanding high operating temperatures up to 550 °C

- Long service life, even under thermal cycling conditions

- Easy to install, replace, and retrofit with segmental design for larger diameters

- Optional thermocouples, sensors, and cutouts available for advanced process control