-

Need help?

+91 9311163794

-

Mail Us @

sales@subhotheaters.com

Tubular Heater

×

❮

![]()

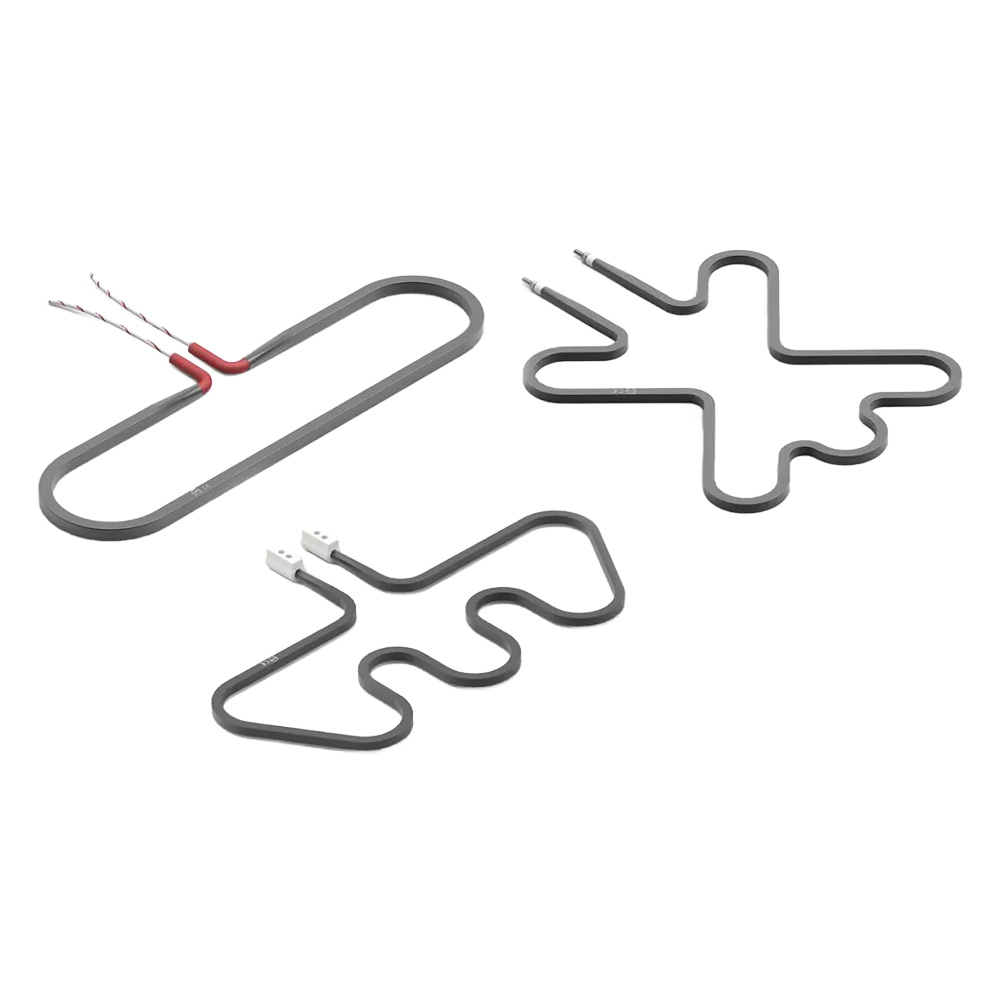

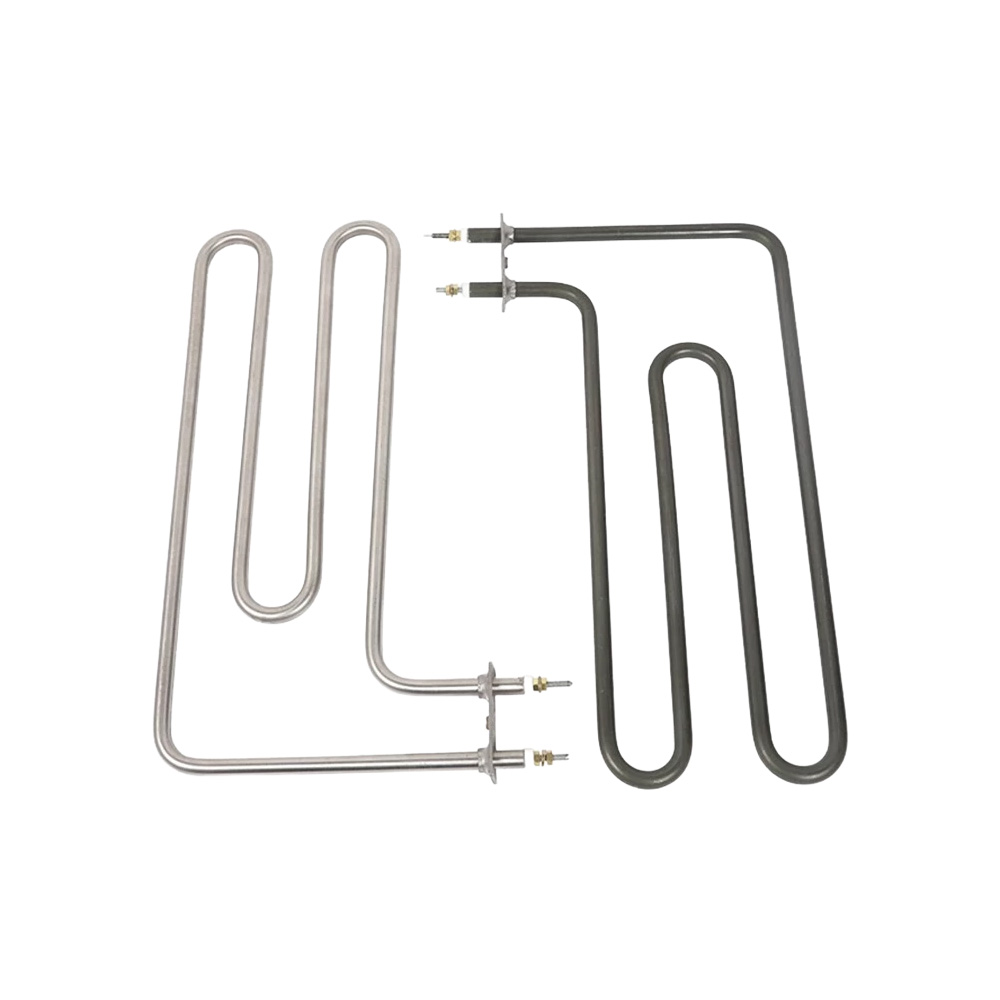

Tubular Heater

Tubular heaters are the most versatile and widely used industrial heating elements, designed for direct heating of air, liquids, solids, and surfaces. Built with a NiCr resistance wire insulated with high-purity magnesium oxide and encased in a metal sheath, they provide efficient heat transfer, durability, and uniform performance.

Available in straight, bent, or custom-formed shapes, tubular heaters are suitable for immersion, radiation, or conduction heating. Their adaptability, robust design, and long service life make them the standard choice for a wide range of industrial and commercial applications.

Advantages

- Highly Versatile – Suitable for air, liquid, and surface heating.

- Customizable Design – Available in straight, bent, or complex shapes.

- Efficient Heat Transfer – Conduction, convection, and radiation heating modes.

- Corrosion Resistance – Wide choice of sheath alloys for harsh environments.

- Rapid Heat-Up – Fast response with uniform heating.

- Durable Construction – Long service life with minimal maintenance.

Applications

- Air Heating – Ovens, dryers, and furnaces

- Liquid Heating – Immersion in tanks, baths, and process vessels.

- Plastics & Rubber – Mould heating and hot runner systems.

- Food Processing – Holding, cooking, and drying equipment.

- Packaging & Sealing – Heat-sealing and shrink systems.

- HVAC & Dehumidification – Heating coils and air conditioning systems.

- Medical – Sterilizers, autoclaves, and laboratory equipment.

Features

- Flexible Mounting – Can be designed in multiple orientations.

- Efficient Heat Transfer – Utilizes conduction, convection, and radiation.

- Uniform Heating – Ensures consistent temperature distribution.

- Corrosion & Oxidation Resistant – Built for industrial environments.

- Custom Sizes – Available up to 10 meters in length.

- Wide Power Range – Supports varied watt densities and voltages.